Additive manufacturing, commonly known as 3D printing, has revolutionized the manufacturing landscape. By enabling the creation of complex and customized products with unprecedented precision and efficiency, additive manufacturing is redefining production processes across multiple industries.

From aerospace to healthcare and even consumer goods, this technology has paved the way for cost-effective and sustainable manufacturing solutions.

In this article, we will explore the impact of additive manufacturing on the global manufacturing industry, its benefits, challenges, and the future potential of this groundbreaking technology.

The Evolution of Additive Manufacturing

Additive manufacturing is not a new concept. Initially developed in the 1980s, 3D printing was primarily used for prototyping. Over the past few decades, technological advancements have significantly enhanced its capabilities, making it a viable option for large-scale production.

Key Milestones in Additive Manufacturing:

- 1980s: introduction of stereolithography (SLA), the first 3D printing technology.

- 1990s: Development of selective laser sintering (SLS) and fused deposition modeling (FDM), expanding material options.

- 2000s – The use of additive manufacturing in medical and aerospace applications gains traction.

- 2010s-Present: Advancements in metal 3D printing and multi-material printing revolutionize industrial applications.

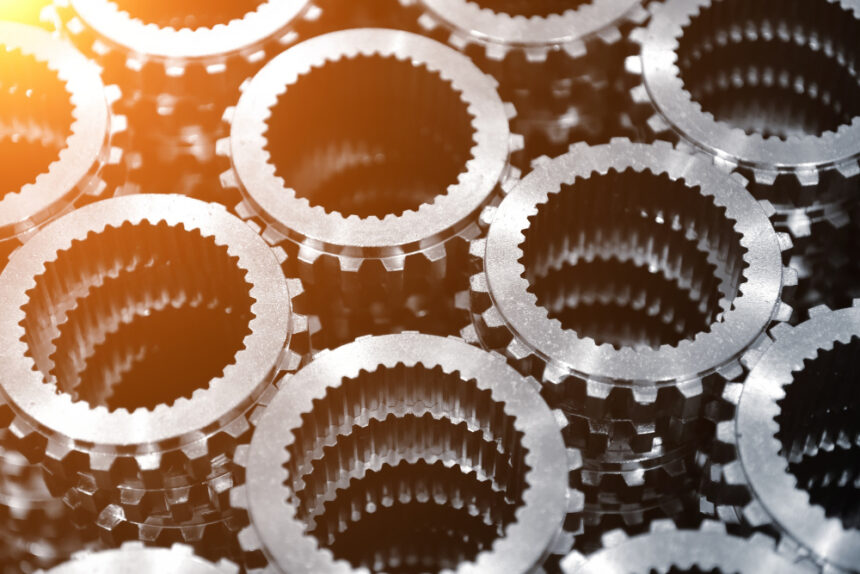

Advantages of Additive Manufacturing in Modern Manufacturing

1. Cost Efficiency

Traditional manufacturing involves expensive molds, tooling, and excess material waste. Additive manufacturing eliminates these constraints by building objects layer by layer, reducing production costs and material waste.

2. Customization and Design Flexibility

3D printing allows manufacturers to create highly customized designs without additional costs. This is particularly beneficial for industries like healthcare, where custom prosthetics and implants can be designed to fit individual patients.

3. Reduced Lead Times

Unlike conventional manufacturing, which may require weeks or months for prototyping and production, additive manufacturing significantly shortens lead times. Companies can quickly iterate and test designs before committing to large-scale production.

4. Sustainability and Waste Reduction

Additive manufacturing is inherently more sustainable than traditional subtractive manufacturing methods, which remove excess material. With minimal waste generation, energy efficiency, and the use of biodegradable materials, 3D printing supports eco-friendly production.

5. Enhanced Supply Chain Resilience

With the ability to produce components on-demand and locally, additive manufacturing reduces reliance on global supply chains. This helps businesses mitigate disruptions, especially in times of crisis like the COVID-19 pandemic.

Applications of Additive Manufacturing Across Industries

1. Aerospace and Defense

The aerospace sector has embraced 3D printing for lightweight, high-performance components. Companies like Boeing and Airbus utilize additive manufacturing to produce intricate aircraft parts that reduce weight, improve fuel efficiency, and lower overall costs.

2. Automotive Industry

3D printing is revolutionizing automotive production by enabling rapid prototyping, on-demand spare parts manufacturing, and innovative lightweight structures. Companies like Tesla and Ford leverage additive manufacturing to enhance vehicle design and performance.

3. Healthcare and Biotechnology

In medicine, 3D printing is used to create patient-specific implants, prosthetics, and even bio-printed tissues. The technology has also facilitated advancements in drug development and regenerative medicine, offering new possibilities in personalized healthcare.

4. Consumer Goods and Retail

From customized jewelry to footwear and home décor, additive manufacturing is transforming the retail sector. Companies like Adidas have integrated 3D printing into their production processes to create high-performance footwear tailored to individual consumers.

5. Construction and Architecture

The construction industry is witnessing a revolution with 3D-printed buildings and infrastructure. Additive manufacturing enables faster, more sustainable, and cost-effective construction, with companies exploring its use for disaster relief housing and space colonization projects.

Challenges and Limitations of Additive Manufacturing

While additive manufacturing offers numerous advantages, it is not without its challenges.

1. Material Limitations

Although material options for 3D printing have expanded significantly, they are still limited compared to traditional manufacturing methods. The availability of durable, high-performance materials remains a challenge.

2. High Initial Investment

Industrial-grade 3D printers and specialized materials can be expensive, making adoption challenging for small businesses.

3. Scalability Issues

While 3D printing excels in prototyping and small-batch production, large-scale manufacturing using additive methods can be slow and costly.

4. Regulatory and Quality Assurance Concerns

Ensuring the quality and safety of 3D-printed products, particularly in industries like healthcare and aerospace, remains a significant challenge. Regulatory frameworks are still evolving to address these concerns.

The Future of Additive Manufacturing

The future of additive manufacturing is promising, with ongoing research and technological advancements driving innovation. Here are some key trends shaping the industry:

1. AI-Driven Design and Automation

Artificial intelligence and machine learning are being integrated with 3D printing to optimize designs, enhance efficiency, and predict manufacturing outcomes.

2. Advancements in Bioprinting

Researchers are making significant progress in bioprinting, with the goal of creating functional human organs for transplantation in the future.

3. Hybrid Manufacturing

The integration of additive and subtractive manufacturing techniques is paving the way for hybrid manufacturing solutions that combine the best of both worlds.

4. On-Demand Production and Digital Warehousing

Additive manufacturing enables digital inventories, reducing the need for physical storage and allowing for on-demand production of parts and products.

5. Sustainable Manufacturing Initiatives

Companies are exploring eco-friendly materials and recycling initiatives to make additive manufacturing more sustainable and environmentally friendly.

Conclusion

Additive manufacturing is redefining the way industries approach production, offering unprecedented advantages in terms of cost savings, design flexibility, and sustainability. While challenges remain, the continued evolution of 3D printing technology holds immense potential for transforming industries and shaping the future of manufacturing.

As businesses and researchers continue to explore the capabilities of additive manufacturing, its impact will extend beyond traditional manufacturing, unlocking new possibilities in medicine, aerospace, consumer goods, and beyond. By embracing this innovative technology, industries can achieve greater efficiency, customization, and sustainability in their production processes.